Home / Belt Scales / Beltway / Low-Profile/Portable Conveyor Belt Scales

Low-Profile/Portable Conveyor Belt Scales $ 0.00

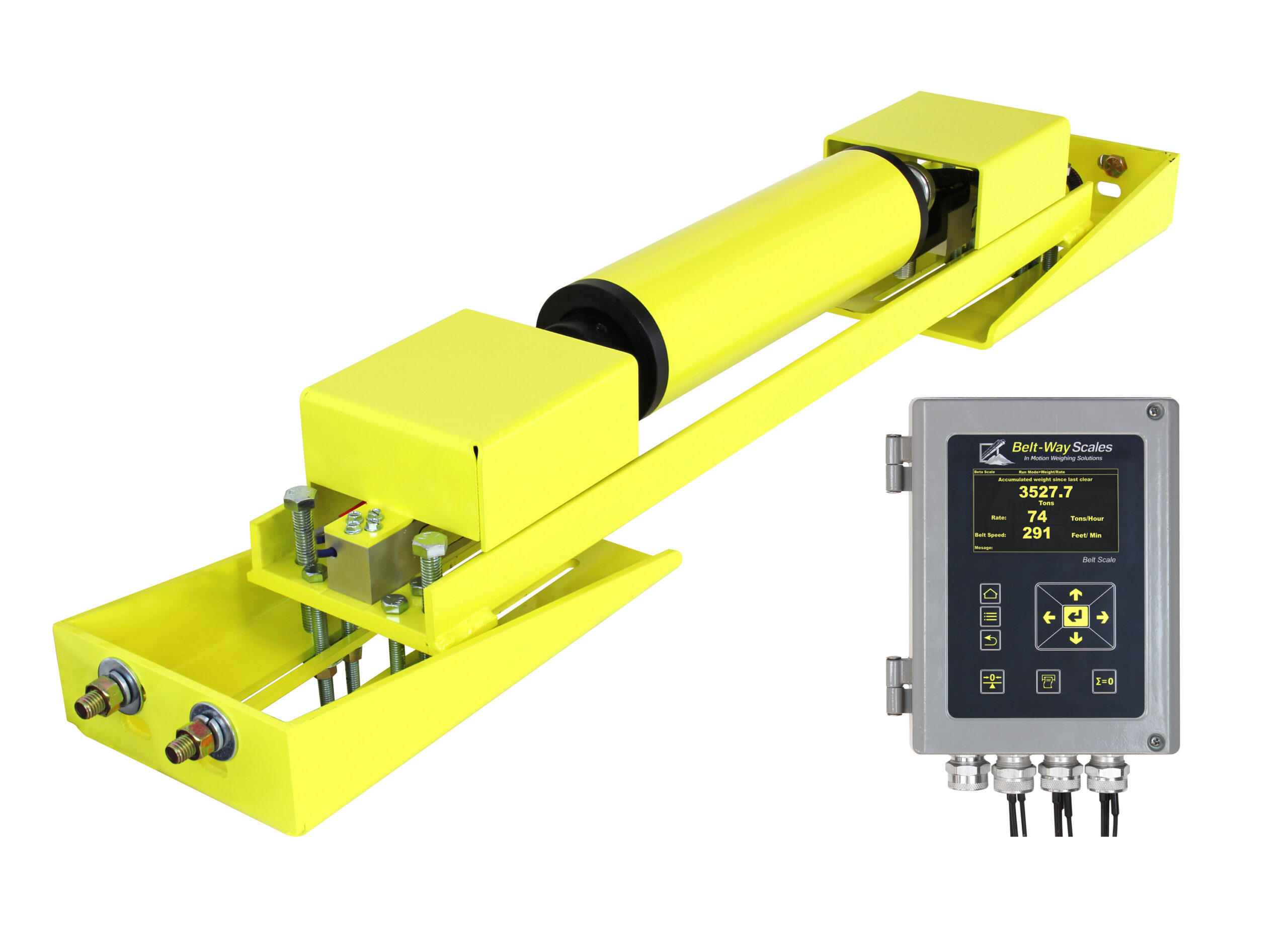

The Belt-Way ROLL-R Scale was specially designed for use on portable equipment such as rock crushers and screeners. The ROLL-R scale is extremely easy to install and gives the user the option to eliminate a dedicated conveyor for the belt scale. Crushers and screeners are very diverse, so Belt-Way designed the ROLL-R scale to be very flexible. It can be installed in between two idlers or be used in place of an existing idler, and there are three options that will fit almost any width conveyor. Please contact Belt-Way to confirm the ROLL-R is best suited for your application.

Download product PDF

Features

Ultra-Low Profile Design

Internal Speed Sensor Installed Inside the Roller

Scale Solution for the Following Types of Machines: KPI-JCI FT4250, McCloskey Screener, Metso Nordberg LT, Powerscreen Chieftain Screen, Rubblemaster RM90, Sandvick QJ340+

Minimal Fabrication Required for Installation Compared to the Standard Model

Specifications

3 Width Options: Standard: Fits Machine Frame 45.5 to 64.5 Inch Frame, Wide: Fits Machine Frame 67.5 to 86.5 Inch Frame, Narrow: Fits Machine Frame 37.5 to 56.5 Inch FrameCalibration: Material test calibration required, automatic zero adjustmentAlarms: Load cell failure, belt speed zeroIntegrator: Utilizes standard Belt-Way integratorCommunications: Ethernet port supports Modbus/TCP; USB port for data download and firmware updatesDisplay: Large color graphic display with multi language supportElectrical Ratings: Input Power: 12-30 VDC, 24 VDC 2.25A Max; AC Power Option: Input: 100-240 VAC, 1A Max, 50-60Hz; Output: : 24 VDC, 2.25A MaxOperating Temperature: -20 C to +45 C (-4 F to +113 F)Load Cell Inputs: Eight independent cell inputs; 9 VDC-250mA nominal supply; +2 mV/VDC (Option 3mV/VDC) nominal signal; 350 OHMS load cell resistanceOn-Board Memory: 1,080 hours of internal memory storageOnline Reporting and Smart Phone App: Each integrator is equipped to connect to Plant Connect

Models

ROLL100-AC-N

Roll-R beltscale 100kg Narrow, AC pwr sply

ROLL100-DC-N

ROLL-R beltscale 100kg Narrow, DC pwr sply

ROLL200-AC-N

ROLL-R BELT SCALE, Narrow Width, AC Power

ROLL200-DC-N

ROLL-R beltscale 200kg Narrow, DC pwr sply

ROLL350-AC-N

ROLL-R beltscale 350kg Narrow, AC pwr sply

ROLL350-DC-N

ROLL-R beltscale 350kg Narrow, DC pwr sply

ROLL100-AC-S

ROLL-R beltscale 100kg Std width, AC pwr sply

ROLL100-DC-S

ROLL-R beltscale 100kg Std width, DC pwr sply

ROLL200-AC-S

ROLL-R Belt Scale, Standard Width, AC Power

ROLL200-DC-S

ROLL-R beltscale 200kg Std width, DC pwr sply

ROLL350-AC-S

ROLL-R beltscale 350kg Std width, AC pwr sply

ROLL350-DC-S

ROLL-R beltscale 350kg Std width, DC pwr sply

ROLL100-AC-W

ROLL-R BELT SCALE, Wide Wdth, AC Power

ROLL100-DC-W

ROLL-R beltscale 100kg Wide Wdth, DC pwr sply

ROLL200-AC-W

ROLL-R BELT SCALE, Wide Wdth, AC Power

ROLL200-DC-W

ROLL-R beltscale 200kg Wide Wdth, DC pwr sply

ROLL350-AC-W

ROLL-R beltscale 350kg Wide Wdth, AC pwr sply

ROLL350-DC-W

ROLL-R beltscale 350kg Wide Wdth, DC pwr sply

RLITE30-AC-18

Roll-R-Lite 30kg 18″ AC pwr sply

RLITE30-DC-18

Roll-R-Lite 30kg 18″ wide, DC pwr

RLITE45-AC-18

Roll-R-Lite 45kg 18″ wide, AC pwr

RLITE45-DC-18

Roll-R-Lite 45kg 18″ wide, DC pwr

RLITE30-AC-24

Roll-R-Lite 30kg 24″ wide, AC pwr

RLITE30-DC-24

Roll-R-Lite 30kg 24″ wide, DC pwr

RLITE45-AC-24

Roll-R-Lite 45kg 24″ wide, AC pwr

RLITE45-DC-24

Roll-R-Lite 45kg 24″ wide, DC pwr

RLITE30-AC-30

Roll-R-Lite 30kg 30″ wide, AC pwr

RLITE30-DC-30

Roll-R-Lite 30kg 30″ wide, DC pwr

RLITE45-AC-30

Roll-R-Lite 45kg 30″ wide, AC pwr

RLITE45-DC-30

Roll-R-Lite 45kg 30″ wide, DC pwr

Select a category

access ramp and pit fame (3)

Accessories (183)

Adapter cable (2)

Bumper Guards (1)

Cleaning and organization (1)

Diagnostic Equipment (1)

ethernet transmitter (2)

Junction Boxes (13)

Labels (4)

Load Cell Hardware (34)

Portability Frame (6)

Printers (61)

Printer Accessories (22)

Printers (34)

Riser stand (1)

Scale Cart (1)

Scanners (7)

Software (13)

Airlines Passenger & Cargo (17)

all type of cable (8)

Balances (87)

Analytical Balances (21)

High Capacity balance (1)

Mechanical Balance (4)

Portable Balances (18)

Precision Balances (26)

TopLoader Balance (13)

Ultra-Micro/Micro (5)

Belt Scales (22)

Beltway (11)

Rice Lake (8)

Chemical Manufacturing (25)

Concrete, Asphalt & Quarries (21)

Dimensioning (9)

Food Manufacturing & Packaging (43)

Food/Retail (21)

Fork Lift Scales / Pallet Jack Scales (9)

Garbage & Recycling (19)

Health Scales (167)

Animal/Vet (23)

Athletic Scale (9)

Baby Scale (23)

Bariatric Scales (6)

Bed Scale (1)

Body Composition Analyzer (3)

Chair Scale (6)

Dialysis Scale (3)

Dietary Scale (6)

Doctor Scale (19)

Handrail Scale (3)

Home Scale (10)

Medical Accessories (10)

standometer (4)

Wheel Chair Scale (23)

In-Motion Scales (7)

Instrumentation (196)

Automated Systems (12)

Indicator Software (22)

Interface (13)

Rinstrum (9)

Indicators / Controllers (126)

Cardinal (29)

MSI (5)

Ohaus (7)

RiceLake (48)

Rinstrum (29)

Sartorius (5)

Intrinsically Safe (8)

Pressure Instrumentation (10)

Remote Displays/Scoreboards (20)

Wireless Communications (19)

Inventory Management Solutions (5)

Lab Equipment Products (97)

Balances (15)

Centrifuges (5)

Dry Block Heaters (4)

Lab Accessories (12)

Moisture Analyzers (9)

Vortex Mixers (4)

Weight Kits (44)

Labeling / Barcoding (5)

Life Sciences (10)

load cell cable (2)

Load Cells (741)

AnyLoad (134)

Artech (5)

BLH (2)

Cardinal (22)

CAS (6)

Celtron (23)

Coti (126)

Custom Load Pins (5)

Flintec (18)

HBM (14)

Interface (6)

Load Pins (3)

Revere (35)

RiceLake (105)

Search By Type of Load Cell (629)

Axle Scale Cell (2)

Canister and Disk (26)

Canister Compression (85)

Compression Disk (14)

Double-Ended Shear Beam (63)

Fluid Dampened Load Cell (4)

Link Beam (11)

Load Button (5)

Load Foot (5)

Planar Beam (5)

Rocker Column (10)

S Type (62)

Single Point (142)

Single-Ended Beam (165)

Spoke Type (2)

Tension Link (8)

Sensortronics (33)

Tedea-Huntleight (31)

Totalcomp (27)

Utilcell (5)

Zemic (20)

Manufacturing (2)

Mechanical Scales (6)

Medical Scales (95)

Athletic Scale (7)

Baby Scale (11)

Bed Scale (4)

Body Composition Analyzer (3)

Chair Scale (7)

Dialysis Scale (1)

Dietary Scale (2)

Doctor Scale (12)

Handrail Scale (3)

Home Scale (3)

Medical Accessories (6)

Stretcher Scale (2)

Wheel Chair Scale (10)

On-Board Weighing (16)

Loader Scales (2)

Truck Weighing (12)

Overhead-Weighing Systems (41)

Crane Scales (20)

Custom overhead Integration/Load Cells (11)

Hanging Scales (2)

Monorail Scales (3)

Tension Dynamometers (7)

Pharmaceutical (18)

Platform Scales (174)

Aviation Scales (11)

Bench Scale Bases (16)

Bench Scale Columns (1)

Bench scale tops (1)

Bench Scales (56)

Checkweighers (7)

Counting Scales (12)

Floor Scales (45)

Portable (22)

Portion Control (6)

Postal/Shipping Scales (11)

relays and racks (1)

Retail Scales (22)

computing scales (5)

Hanging Scale (1)

Labeler (1)

PC Scale (1)

Remote scale base (1)

Scale Protection / Guards (2)

Scrap Metal (13)

Software (7)

Test Weights (78)

Class F Cast Iron Test Weights (16)

Weight Kits (52)

Transmitters (2)

Transport/Logistics (20)

Uncategorized (28)

Vehicle Weighing Systems (95)

Axle Scales (6)

Bulkweighers (1)

In-Motion Vehicle Scales (6)

Onboard Truck Weighing (10)

Portable Vehicle Scales/ Axle Pads (11)

Rail Scales (8)

Truck Scales (23)

Vehicle Scale Accessories (27)

Weigh Modules (125)

Anyload (27)

Cardinal (16)

CAS (4)

HBM (1)

Ricelake (42)

Rinstrum (6)

Totalcomp (14)

VPG Revere (7)

VPG Sensortronics (5)